Government of India Registered & ISO Certified Organization

Download the Syllabus : Click Here

Theory of PLC

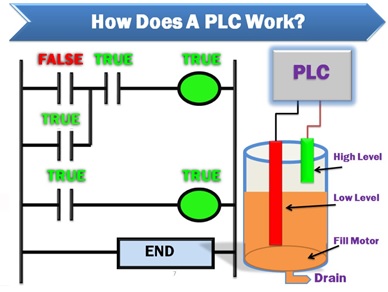

- Introduction to PLC

- Types of PLC

- PLC VS Microcontroller

- PLC Advantages & PLC Applications

- Introduction to PLC Hardware

- How to select the PLC for Projects

- Introduction to I/O Devices (Digital only)

- Introduction to Logic Gates

- Introduction to Ladder programming, Ladder Symbols, function Blocks.

- Syntax & its error

- Scanning of I/O in ladder

- Benefits of ladder programming

- Designing Single Rung & network

- Designing Multiple & branching Rungs & networks

- Learning algorithms for Practical applications.

- Introduction to PLC Trainer 100A

- What is Automation Control & Project management

- Writing of Alarms in PLC And Interface,Ack in HMI/SCADA

- Analog Input/Output Programming

- Analog Input Reading,Averaging,Scaling etc

- Analog Output writing,Scaling for field Devices

- Programming for 4-20mA,0-10v Analog Input Signals

- High Speed Counter

- Use of high speed counter in Ladder Programming,

- Application of High speed Counter

Theory of VFD

To study Functions of VFD Switches & Symbols.

- To operate motor using VFD Console switches.

- To change parameter settings.

- Selection of VFD for Application.

- To change Ramp Down time [deceleration time].

- To change Ramp up time [acceleration time].

- To set output frequency limit [Maximum].

- To set output frequency limit [Minimum].

- Introduction of Modbus Communication of VFD with PLC .

- Troubleshooting of VFD

Practicals on PLC & VFD

- Wiring of Input devices Push buttons Limit switch to the PLC.

- Wiring of output devices from PLC to Relay Contactor and Solenoid Valves.

- Wiring of Level Sensors Pressure sensor to the PLC

- Wiring of Analog output from PLC to different devices.

- Programming Of Analog Input and Output in PLC

- Configuration of PLC – CPU Hardware with the Software

- PLC Ethernet / Profibus / RS 232 Comport Configuration with work station.

- Creating new Project for Conveyor Control/ Fan Control/ Pump Control with different industry based Application.

- Creating Interval control systems for Process Applications with TIMER COUNTER and commands

- Configuration of High Speed Counters with PLC and Its

- Plant Graphic Control Interfacing Program with Monitoring systems.

Motor Starter

- Start/Stop Push button with Motor overload & High temp i/p

- Motor Directions control For-Rev direction with delay & interlock Protections

Conveyor Systems

- Material conveyor with Counter

Traffic Light control

- Traffic Light controller 4 lane

Water Level controller

- Water level controller with pump

Download the Syllabus : Click Here